Understanding the Universal Testing Machine (UTM)

The Universal Testing Machine (UTM), also referred to as a Universal Tester, Materials Testing Machine, or Materials Test Frame, serves as a pivotal tool extensively employed across various industries and laboratories worldwide to gauge the strength of materials. It operates by subjecting materials to varying pressures, strains, and loads, enabling a comprehensive understanding of their behavior.

Components of a UTM

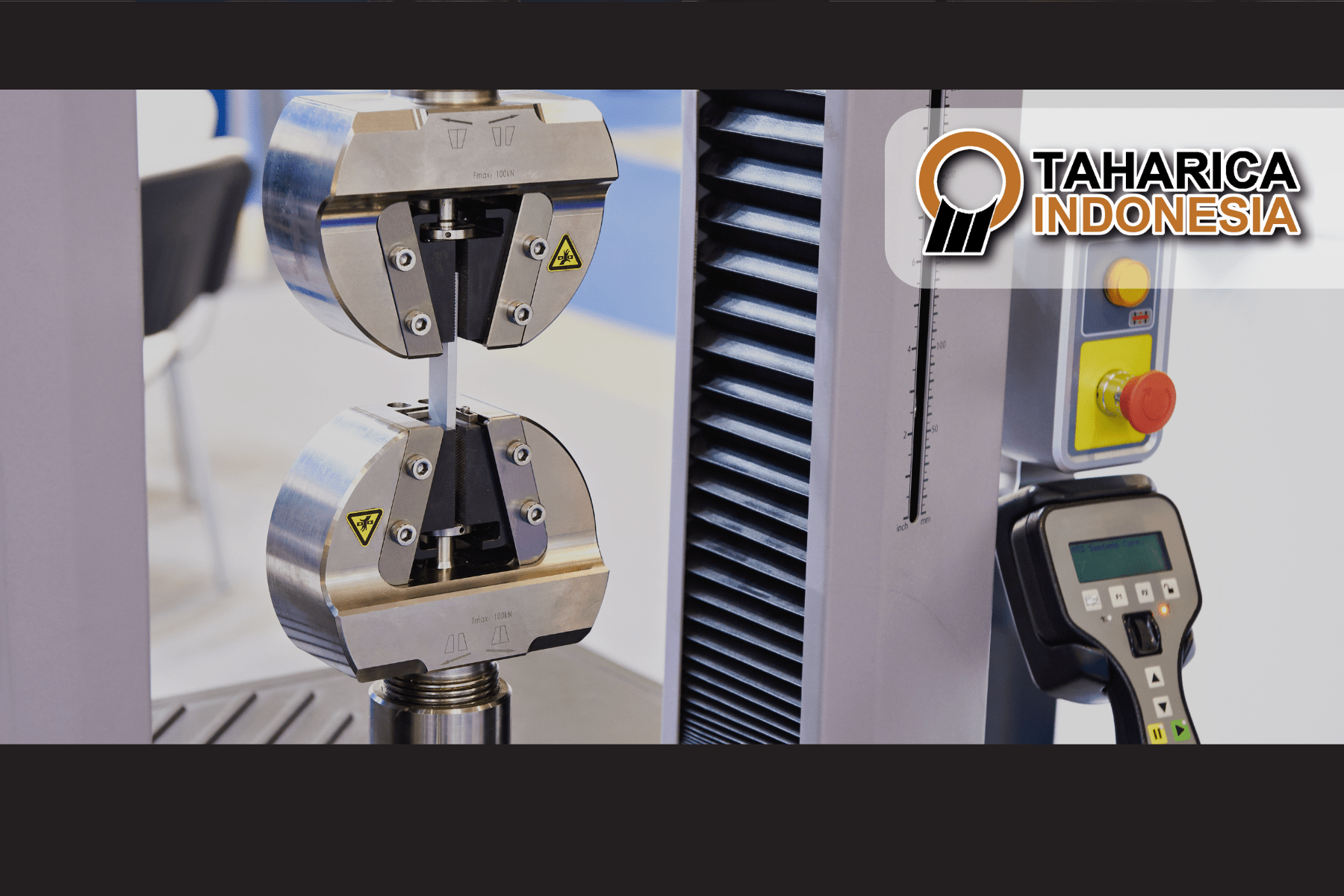

- Load Cell and Engine Motor : At the core of a UTM lie essential components like the load cell, measuring applied forces, and the engine motor, providing power to the machine.

- Frame and Crosshead: The sturdy frame supports the entire structure of the UTM, while the crosshead facilitates the controlled movement or pulling of material samples during testing.

- Actuators and Control Panel: Actuators drive the crosshead’s movement, ensuring precise testing conditions, while the control panel allows for seamless management of UTM operations.

- Controlling Software: Sophisticated software controls and analyzes the test data, enabling comprehensive evaluation and insights.

Testing Methods

UTMs are utilized for two main testing methods: Tensile Testing, where materials are gradually pulled until failure or fracture occurs, and Compression Testing, which involves applying pressure until deformation or failure is observed. These methods are instrumental in evaluating the strength and resilience of materials across diverse conditions. Furthermore, UTMs are versatile instruments capable of testing various materials ranging from metals to plastics, rubbers, woods, and concrete.

Data Accuracy and Decision Making

The data generated by UTMs are highly accurate and reliable, empowering engineers and researchers to make informed decisions regarding material selection for construction projects or manufacturing processes.

By harnessing the power of UTMs and their comprehensive testing capabilities, industries can ensure the quality, reliability, and safety of materials used in diverse applications.

Advantages of Universal Testing Machine (UTM) Usage

Comprehensive Material Strength Evaluation

The utilization of Universal Testing Machine (UTM) enables a thorough assessment of material strength, encompassing crucial properties such as tensile strength and compressive strength. By subjecting materials to controlled forces, UTM facilitates precise measurements, providing insights into the resilience and durability of various substances.

Extensive Material Testing Capabilities

UTM offers a diverse range of material testing functionalities, allowing for the determination of mechanical characteristics essential for engineering applications. Through UTM, parameters like elastic modulus, shear modulus, and hardness values can be accurately determined, aiding in material selection and design optimization processes.

Quality Assurance and Verification

One of the significant advantages of employing UTM is its capacity to conduct systematic quality tests, ensuring that manufactured materials adhere to industry standards and specifications. By verifying the quality of materials through rigorous testing protocols, UTM contributes to enhancing product reliability and customer satisfaction.

Facilitation of Research and Development Efforts

UTM plays a pivotal role in research and development initiatives by providing researchers with valuable insights into the mechanical properties of different materials. Through comprehensive testing and analysis facilitated by UTM, researchers can make informed decisions regarding material advancements, leading to the development of innovative products and technologies.

Precise Data Generation and Analysis

The sophisticated instrumentation and software integration of UTM enable the generation of precise and reliable data, essential for informed decision-making in various industries. By accurately measuring material responses to applied forces, UTM contributes to the optimization of material performance and structural design.

Versatility Across Industries and Applications

With its capability to test a wide range of materials, including metals, plastics, rubbers, woods, and concrete, UTM proves to be a versatile tool applicable across diverse industries. From automotive and aerospace to construction and manufacturing sectors, UTM serves as a universal platform for material testing and evaluation.

In essence, the adoption of Universal Testing Machine (UTM) offers a multitude of benefits, ranging from comprehensive material assessment to quality assurance and research facilitation. By leveraging the capabilities of UTM, industries and research institutions can achieve enhanced product quality, performance, and innovation.

More Info :

Whatsapp/Mobile Support :

0815-9072-797 (Mrs.Sri)

0812-9595-7914 (Mr.Parmin)

Phone : +62 21 8690 6777

Fax : +62 21 8690 6770

Email : sales@taharica.com

www.taharica.co.id I www.taharicaindonesia.com