What is a Tensile Test?

As someone interested in the fields of manufacturing, construction, or engineering, you’ve likely heard the term “tensile test.” But what exactly lies behind this seemingly complex term? Let’s delve into it together. A tensile test is a crucial process for evaluating the strength and durability of materials. In manufacturing, construction, and engineering industries, a deep understanding of the mechanical properties of materials is essential for producing high-quality and safe products.

Function of the UTM

The Universal Testing Machine (UTM) is fundamental in conducting tensile tests. With its capability to apply controlled and gradual loads to material samples and record their responses, the UTM enables us to understand material behavior in detail. The main components of this machine include the frame, the driving mechanism, the load system, and the control software. These components work together to perform precise and accurate tests.

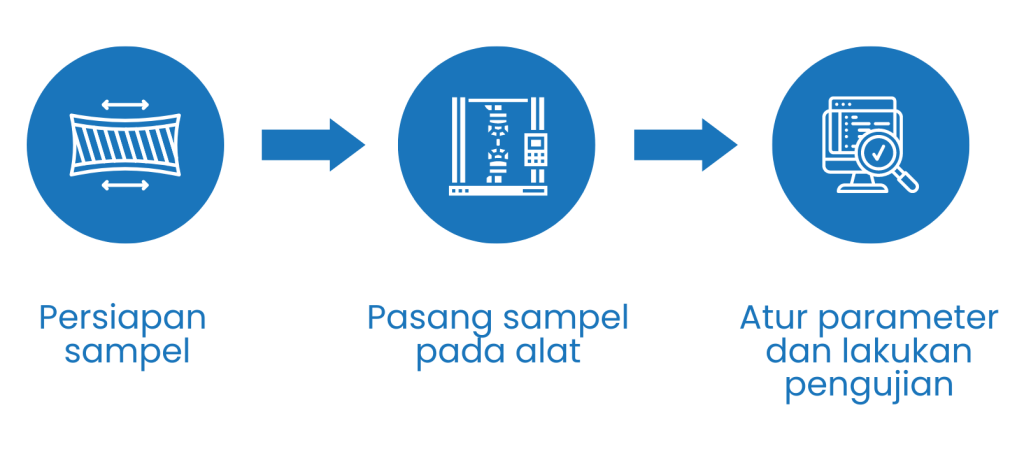

Tensile Test Procedure

The steps involved in a tensile test include preparing the sample, mounting the sample on the machine, setting test parameters such as loading rate, and executing the test. Once the sample is tested, the data obtained can be analyzed to extract critical information about the material’s mechanical properties. This data helps in understanding how the material will perform under various conditions.

Parameters Measured

The primary parameters measured during a tensile test include stress, strain, modulus of elasticity, ultimate tensile strength, and breaking point. By understanding how a material responds to applied loads, we can make more accurate predictions about its performance in different applications. This information is invaluable for engineers and designers who need to select the right materials and design efficient and safe structures.

Application of Tensile Testing in Various Industries

Tensile testing has widespread applications in industries such as automotive, aerospace, building materials, and more. The results of tensile tests enable engineers and designers to choose appropriate materials, design efficient structures, and ensure product safety. The data derived from these tests is crucial for making informed decisions in the development and production processes.

Challenges in Tensile Testing

Challenges that may be encountered during testing include the influence of temperature, sample size inconsistencies, and accurate sample preparation. However, with proper adjustment strategies, such as using thermal protective devices and advanced sample preparation methods, these obstacles can be overcome. Ensuring that the testing conditions are controlled and standardized is key to obtaining reliable results.

Technological Developments

Recent advancements in tensile testing technology have significantly improved the efficiency, accuracy, and capabilities of the UTM. Innovations such as more sensitive sensors and sophisticated data analysis software continuously push the boundaries of what we can achieve in understanding materials. These advancements allow for more detailed and accurate insights into material properties, enhancing our ability to innovate.

Conclusion

In conclusion, the tensile test is an invaluable tool in our understanding of materials and their applications in the real world. The implications of test results for industry and society are immense, ensuring that the products we use daily are the best in their class. With the use of UTM and a deep understanding of tensile testing, we can unlock unlimited innovation potential across various industries. Let’s continue to explore and uncover the potential of materials with greater precision.

By using UTM and gaining a thorough understanding of tensile testing, we open doors to endless innovations in multiple industries. This thorough exploration of material properties not only enhances our technical capabilities but also ensures that the products we develop are safe, reliable, and of the highest quality. The meticulous analysis and testing procedures underpinning tensile tests contribute to advancements in engineering and manufacturing, driving progress and setting new standards in material performance and product excellence. The tensile test, therefore, is not just a method of evaluating material strength; it is a gateway to pioneering developments and groundbreaking achievements in technology and industry.

More Info :

Whatsapp/Mobile Support :

0815-9072-797 (Mrs.Sri)

0812-9595-7914 (Mr.Parmin)

Phone : +62 21 8690 6777

Fax : +62 21 8690 6770

Email : sales@taharica.com

www.taharica.co.id I www.taharicaindonesia.com