The factory is a very complex location with a variety of soil and geological structures that affect the stability and safety of the area. For factory owners, understanding the potential risks arising from changes in soil and geological conditions is crucial. In overcoming this, the application of a Geotechnical Monitoring System in the factory area is the right solution to observe potential geotechnical problems. This article will discuss the advantages, roles, and implementation of the Geotechnical Monitoring System in factories, and its positive impact on increasing safety, efficiency and safety at work.

Benefits of Using a Geotechnical Monitoring System in Factory Areas

A Geotechnical Monitoring System is a system that utilizes sensors and state-of-the-art technology to measure changes in soil and geological conditions in real time. Its main advantages include:

- Identifying Potential Obstacles: Geotechnical Monitoring Systems allow early detection of changes in soil and geological conditions, such as soil movements, moisture levels and deformations. This way, preventative measures can be taken by the manufacturer before the problem becomes more serious.

- Improve Structural Safety: Through continuous monitoring, Geotechnical Monitoring Systems help prevent failures of soil structures that have the potential to threaten the safety of workers and plant property.

- Improving Occupational Safety: By detecting potentially hazardous changes in soil and geology, workers can be evacuated quickly and appropriately when an emergency situation occurs.

- Increase Efficiency: Real-time information provided by the system enables more informed and efficient decision making in operating the factory.

- Reducing Environmental Impact: Through careful monitoring, potential environmental damage due to geological changes can be minimized, allowing factories to operate in a more sustainable and responsible manner.

Geotechnical Monitoring System to Prevent Threats of Failure of Soil and Geological Structures in Factory Environments

The application of the Geotechnical Monitoring System has the capability to recognize and prevent the risk of failure of the soil structure and geology in the factory area.

When a change approaches a critical threshold, the system issues an early warning to interested parties, allowing corrective steps to be taken before the risk becomes apparent.

In addition, this system also allows long-term analysis of the environmental impact of the plant on soil stability. This data collected over a wider span of time supports engineers and plant owners in future planning, maintenance and development of structures that are more robust in the face of changing environmental conditions.

Parameters Monitored by the Geotechnical Monitoring System at the Factory

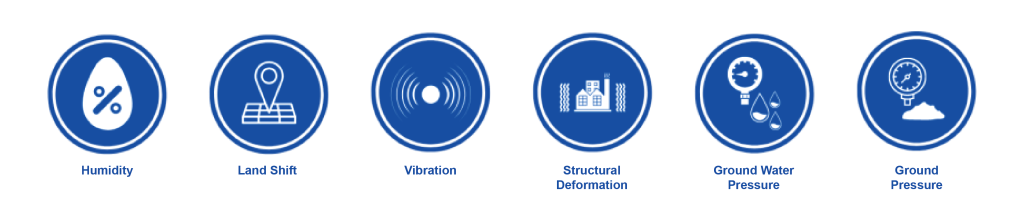

Geotechnical Monitoring System can monitor various important parameters, including:

- Ground Movement: Traces of displacement, subsidence, or horizontal movement of soil around plant structures.

- Earth Pressure: Assess the compressive force of the soil which has the potential to affect the stability of the foundation and building structure.

- Soil Moisture Content: Monitoring the level of water content in the soil to prevent erosion or decrease in stability.

- Structural Deformation: Examination of deformations in building structures and foundations to detect potential cracks or damage.

- Environmental Vibration: Monitor vibrations generated by plant activities or external factors, which have the potential to affect structural integrity.

- Groundwater Pressure: Monitoring of groundwater pressure to prevent impact on foundations and subsurface structures.

The Contribution of the Geotechnical Monitoring System in Increasing the Efficiency and Reliability of Factory Operations

The Geotechnical Monitoring System makes a major contribution in increasing the efficiency and reliability of plant operations through:

- Real-time Monitoring: Real-time information enables quick and informed decision-making, reducing the risk of downtime and decreased production.

- Preventive Maintenance: By detecting potential problems at an early stage, maintenance can be carried out preventively, preventing serious damage and high recovery costs.

- Investment Plan: Long-term data collected through the system helps in planning long-term investments for infrastructure improvement and plant development.

- Land Use Optimization: By understanding how the environment affects land, mills can optimize the use of available land.

Latest Technology in Geotechnical Monitoring System for Factories

Geotechnical Monitoring System technology continues to grow rapidly, and some of the latest innovations used in factories are:

- Wireless Sensor Networks: Sensors that function wirelessly allow for simpler and more flexible installations without the need for the use of complex cabling.

- Big Data Analytics: Advanced data analysis techniques enable deeper understanding of soil behavior and geology.

- Internet of Things (IoT): Connecting sensors online allows real-time access to data and remote monitoring.

- Machine Learning: Machine learning methods allow systems to recognize patterns and trends that are difficult to access through human analysis.

For Geotechnical Safety Monitoring System Services:

Whatsapp/Mobile Support :

0815-9072-797 (Mrs.Sri)

0812-9595-7914 (Mr.Parmin)

Phone : +62 21 8690 6777

Fax : +62 21 8690 6770

Email : sales@taharica.com

visit our other website : www.taharica.co.id